Weight Distribution Video

Torklift's guide to weight distribution

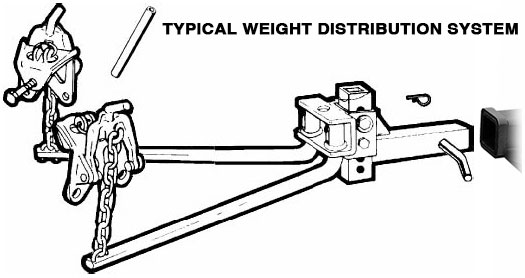

This type of hitch is required in addition to your SuperHitch to obtain the maximum rated capacity. Incorrect installation of the weight distribution system may result in damage to your vehicle.

When towing trailers that exceed the dead weight rating on your extension it is mandatory to use a weight distributing type hitch/ball mount and related hardware (Springbars, Quick Hookup Clips, ect.).

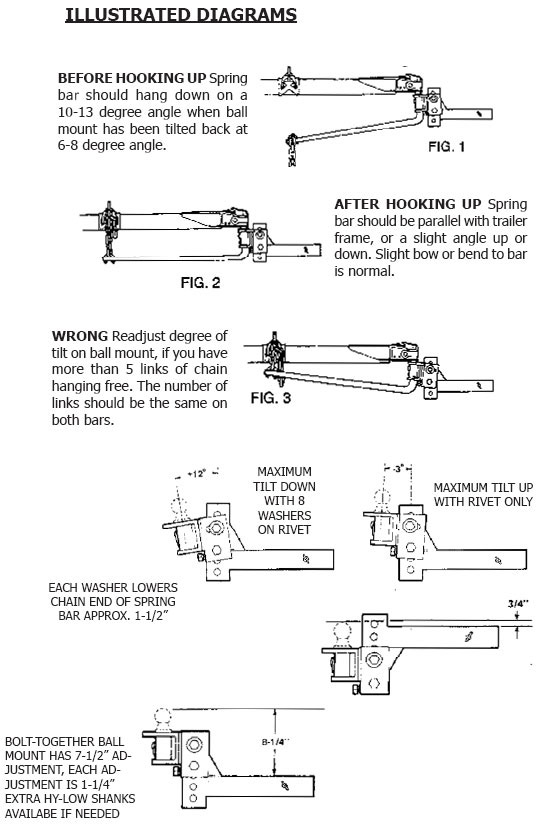

Not all weight distribution systems are rated at the same capacity. Your weight distributing ball mount and bars must be rated at least 100lbs higher in regards to tongue weight, then your pre-existing tongue weight of your trailer when fully loaded.

It is of critical importance that your weight distribution system is not only rated high enough to match your exiting tongue weight, but that you also have the system set up correctly.

We have supplied a formula to assist you in accurately determining the tongue weight load of your trailer when fully loaded. After accurately determining your tongue weight and making sure that your weight distribution system is rated high enough, your next step is to ensure that setup of the system is correct.

PLEASE READ CAREFULLY

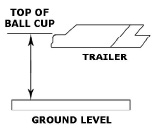

1. The height of the ball must be determined before any assembly work and be started. To get the ball height measure the trailer from the ground level to top of ball coupler. Be sure trailer is parallel to ground. With your camper on your truck, fully loaded with gear and overloads adjusted, slide the weigh distribution ball mount into the SuperHitch extension. Be sure the truck is on level ground. The measurement from ground to top of ball should be 1 1/2 higher than the level height of trailer top of ball measurement.

2. After ball height has been determined write down the ascertained height. EXAMPLE: Measured top of coupler height was 17" from ground, ball height should be 18 1/2".

3. Slide the shank into the sleeve receiver, insert hitch pin and spring clip. With the ball attached to the ball mount, slide the ball mount up or down the shank until the nearest dimension is obtained and the holes line up with the shank. Insert the bolt in the bottom hole first (rest hitch head).

4. The rivet and 8 spacer washers are supplied in order to gain the correct downward angle of the spring bars. Insert rivet, and depending on the angle or slope of the bars that must be gained, use either 8 or the least amount of washers necessary in order to establish correct angle. The rivet and its accompanying washers are placed in the 1/2" hole between the "U" on the ball mount to quire desired angle of spring bar. Once the spring bar angle has been determined, insert top bolt with a flat washer, both sides, the lock-washer, and nut to secure the unit in correct position, now insert bottom bolt, use the lock washer and nut. Before tightening the bolts, lock the set screw. (After the first day of towing, check the screw for tightness).

These steps may vary depending on weight distribution hitch manufacturer

1. Put the ball mount into the sleeve and insert the 5/8" hitch pin using spring clip to lock the pin into place, hitch balls are not furnished with the hitch as there are several sizes. Normally they are supplied or may be purchased from dealer to match the coupler of the trailer. Ball shank bushings are supplied to reduce the size of the ball hole in the hitch down to 1" if needed.

2. Measure the towing vehicle ball height before adding load to towing vehicle. Hook the trailer to the truck. Lock on the ball. To make hooking up easier and safer - raise the from of the trailer and back of the towing vehicle above level with the trailer tongue jack. This removes some of the tension by reducing the distance between the spring bar and hook-up point.

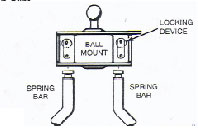

3. This step may vary depending on the manufacturer. The spring bars can be inserted into either side of the ball mount. (There is no 'right' or 'left' bar). To insert and lock spring bar in socket, hold the bar under socket and push up. The spring bar will automatically be locked into position by the spring bar locking device. (Check to make sure the bar is locked in by moving it up and down at the chain end.) To remove the spring bars, just pull out the locking device or swing the bar around under the bumper and it will drop free.

4. To find correct location on trailer frame for quick hook-up bracket, hold the chain straight up and down and free of twist center hook-up bracket on frame and tighten. Set the screw 1/4 turn only. DO NOT OVER TIGHTEN. On straight tongue trailers a poli-tongue adapter is necessary.

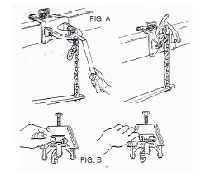

5. You are now ready to put the tension on the spring bars. When using the quick hook-up, lower the arm and slip link of chain over hook. Insert hook-up handle over the end of the quick hook-up arm, lift and flip over center. (See Fig A.)

CAUTION: Make sure that the hook-up arm is completely seated and that the spring bar is pushed directly under the hook-up chain hook. Now install the hook-up locking clip though locking ears and over hook on hook-up arm. (See Fig B.)

6. Release the trailer tongue jack by adjusting the chain links up or down, the desired load on the bars will be gained. Now lock the coupler on to the ball and raise the front of the trailer approximately 3" above level. Now attach the chain link to the hook-up clip. It should required 50-100 lbs. of force to properly tension the spring bars. Bow or bend to the spring bar is normal.

7. To release tension on the spring bars, raise the front of the trailer and the back of the towing vehicle above level (approx. 3") with the trailer tongue jack. Remove the locking clip from the bracket. Insert the handle over arm. Carefully lower the arm with the handle. It will require effort to bring the arm over the center and then to resist the chain tension as the arm rotates downward.

MAINTENANCE:

Use heavy lubrication such as fiber type wheel bearing grease on the hitch ball and on spring bars inside the ball mount. This is recommended every day. Also keep the hitch painted to prevent rust and check the tightness of bolts regularly. Clean out the old grease and do not let it harden inside the ball mount.

Important consumer information on towing

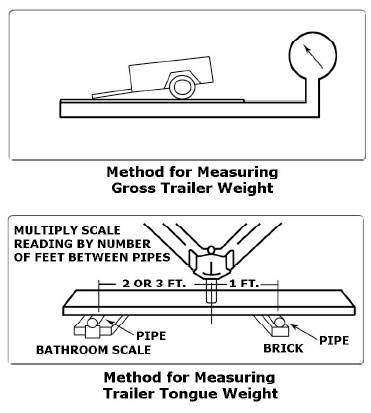

Towing equipment owners: Make sure all of the operators of your equipment read and understand this information before towing. Save for reference. This will help you properly select, use and maintain your towing equipment. Refer to your owner's manuals for your tow vehicle, trailer and other parts of your towing system. Learn the capabilities and limitations of each part. The gross trailer weight and tongue weight are two of the most important items to consider. These weights must never exceed the lowest rating of any part of your system. Gross trailer weight is the weight of the trailer plus all cargo. Measure the gross trailer weight with the fully loaded trailer on a level surface. The weight is the downward force exerted on the ball by the trailer coupler. Measure the tongue weight with the fully loaded trailer on a level surface. The coupler must be at it's normal towing height. Use a commercial scale or bathroom scale. Set up the bathroom scale as shown for heavy tongue weights.

Your towing equipment

Hitch Balls

Select by gross trailer weight rating, mounting platform thickness, hole size and coupler socket size. Platform must be at least 3/8 inch thick. Hole must not exceed threaded shank diameter by more then 1/16th inch. Use lock washer. Tighten per instructions. When tightened, shank must protrude beyond bottom of nut. Gross trailer weight rating and ball diameter are marked on REESE balls.

Trailer Couplers

The coupler socket should be smooth, clean and lightly lubricated. Tighten or adjust per coupler manufacturer's instructions.

Safety Chains

Connect safety chains properly EVERY TIME YOU TOW. Cross chains under coupler. Attach securely to the hitch or tow vehicle so they can't bounce loose. Leave only enough slack to permit full turning. Too much slack may prevent chains from maintaining control if other connections separate. Don't let chains drag on the road.

Trailer Lights, Turn Signals, Electric brakes and break away switch Connections

Make these safety-critical connections EVERY TIME YOU TOW, no matter how short the trip. Check operation, including electric break manual, before getting on the road.

Sway Controls

Sway controls can lessen the effects of sudden maneuvers, wind gusts and buffeting caused by other vehicles. We recommend them for trailers with large surface areas, such as travel trailers. Adjustable fiction models can help control trailers with low tongue weight percentage.

Other Useful Equipment

AIR SPRINGS, AIR SHOCKS, and HELPER SPRINGS are useful on some applications.A TRANSMISSION COOLER may be necessary for heavy towing. Many states require TOWING Mirrors on both sides.

Tire Inflation Check often. Follow tow vehicle and trailer manufacturer's recommendations. Improper tire inflation can cause trailer sway.

No Passengers in Trailers:

NEVER allow people in trailers while towing, under any circumstances.